Air is invisible, does not have a taste, has no odour and is not tangible. No living creature on earth can exist without it, as “air is essential for living”. Air automatically enters the bloodstream by breathing and supplies the organs with oxygen. A person can survive without air for only a few minutes. While food is a deliberate activity and every person can decide what is on the table, the oxygen supply is unconscious. How many times have you thought about what you let into your body 12 to 18 times a minute?

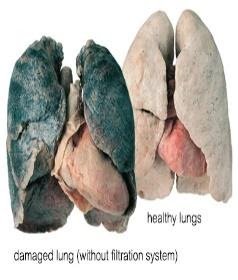

The pollutant concentration increases especially in manufacturing processes, according to the National University of Singapore. Even though every human body has its filters, such as the cilia in the trachea and bronchi, or the lungs, they can only digest organic particles. Industries mostly process metal, which is inorganic and therefore harmful to employees when inhaling its dust. Due to their tiny particle sizes of only a few micrometres, they are mostly invisible to the human eye. This leads to underestimating the danger of metal dust and similar inorganic emissions. The chances of getting severe diseases such as lung cancer and allergies are highly increasing. Only an extraction system can filter these particles and prevent employees from breathing in contaminated air.

An air conditioner only whirls up the particles in the air, much like a kitchen blender. Ventilation leads to an exchange between the indoor and outdoor air. In large cities, however, the pollutant values are close to the permissible limit values of 50 micrograms per cubic meter. The outside air is heavily loaded and brings even more pollutants into the room when aerating. A filter and extraction system draws in the polluted air, which results in particles sticking to the integrated filters. The cleanroom air is then recirculated and safe for breathing.

Investing In Employee Safety Brings Better Results

In the long term, employees are more productive and effective if they are less susceptible to diseases caused by dust in manufacturing processes. As an employer, health and safety should be paramount for all employees, especially those that work in high-risk manufacturing processes. The small investment in an extract dust machine can save thousands in production downtime and employee work claims due to ill health. Providing a safe workplace will lead to healthier employees and will motivate them to increase production.

According to a 2006 study of the Federal Institute for Occupational Health and Safety, the third most common disease is related to respiration. As a result, annual production losses of millions of dollars are incurred. Small particles settle in the lungs and make breathing difficult. Most people often regard air as common property, but the quality is respected too rarely. Industries that require dust and fume extract machines include laser technology, soldering, wood sanding, kitchen bench grinding, welding, gluing, textile, and plastics manufacturing. Dust extract machines can be small mobile units or large stationary units with multiple filters.

TBH dust extract machines with low noise levels are made in Germany and are engineered to filter out the smallest particles. By using HEPA filters and pre-filters, these machines ensure the safety of employees during manufacturing processes. The extract machines are designed for all types of manufacturing processes ,carbon filters combined with HEPA filters for cleanrooms are available at Opira. Simply contact us – we can design and advise on the best extract unit that will keep your employees and or stakeholders safe in any industry.

-Written by Dean Cooper, March 2021.