Product Details

MINIfume

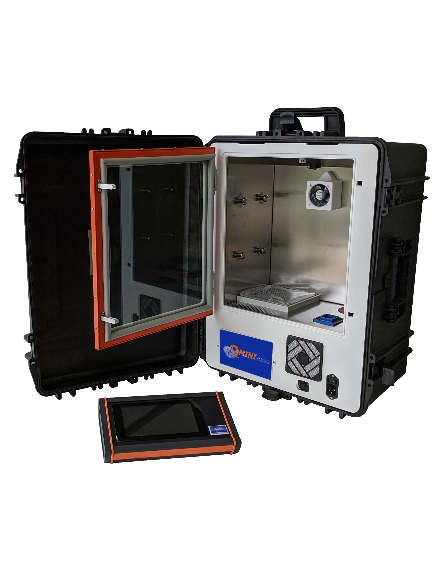

The MINIfume is the mobile cyanoacrylate fuming chamber for developing fingerprints on non-porous surfaces.

Cyanoacrylate (superglue) fuming is a method for developing fingerprints on non-porous surfaces, such as metal, glass, and plastics. Our MINIfume series has been developed specifically for those who need all the high quality and reliability of a fuming laboratory chamber with the flexibility of a mobile unit suitable for use at a crime scene or office.

In addition to our MOBIfume series, intended for larger spaces, we also offer MINIfume, designed to quickly and reliably develop small quantities of evidence on the go. MINIfume brings the laboratory to the evidence.

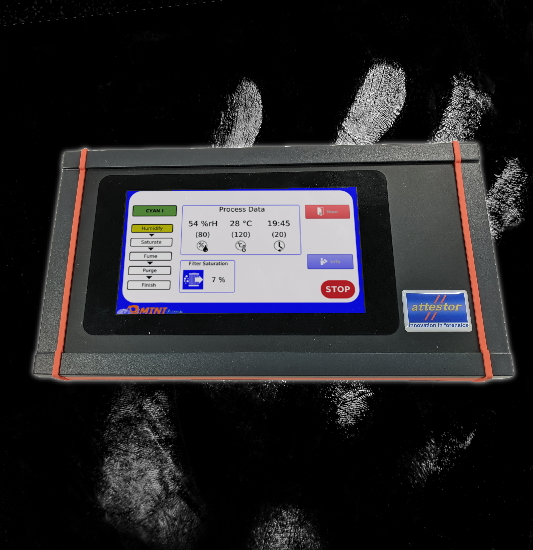

MINIfume has the convenient features of the larger MEGAfume models, complete with pre-programmed and customizable evidence development cycles, active filter and cycle monitoring via a multilingual colour touch-panel display, and an easy-to-clean interior.

- Suitable for fuming smaller objects like knives, handguns, and bottles.

- An activated carbon filter cleans chamber air.

- Datalogger can record and view parameters.

Innovative Interior Design Concept

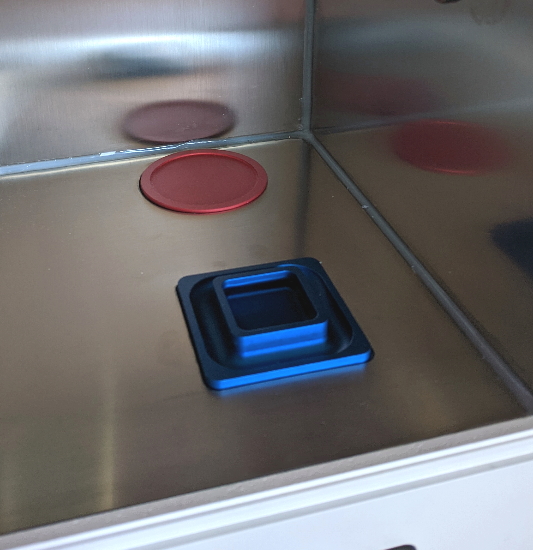

Our cabinet design includes construction with high-quality and durable stainless steel construction. The cabinet interior includes a tempered safety glass viewing panel in the chamber door.

Not only does this still let users view their evidence as it develops, but it also makes the chamber easy to clean after use and resistant to cleaning agents needed for DNA decontamination, like alcohol and peroxide-based solutions.

All our MEGAfume parts, including the water reservoir and circulation fan, can easily be removed from the chamber. In addition, all evidence rods and support shelving be rearranged or removed without tools and conveniently fit a laboratory dishwasher. Our MEGAfume parts are all constructed from stainless steel and made durable and resistant to harsh cleaning solutions needed for DNA decontamination.

MINIfume is housed in a durable rolling case, with all accessories stored in a laser-cut foam storage insert, making it compact and practical for storage and transportation.

Innovative Control System

Users control all MINIfume functions via a sizeable multilingual colour touch panel display on the front of the unit, using the same system as the larger MEGAfume models. Users can quickly select and run one of our pre-programmed cycle options for typical cyanoacrylate developers, modify and save programs, or fully customize and save their cycle settings. The system also allows users to run cycles automatically once they are started or manually control each cycle step if needed.

Humidity, fuming temperature, and even cycle step time are all customizable, making the system simple to use with various developers.

Effective with standard cyanoacrylate and fluorescent one-step developers. The customization options allow for using more uncommon cyanoacrylate developers, enabling adjustment of settings to accommodate developers that are not yet on the market.

Innovative Filter Management

After each cycle is complete, a high-quality low-dust carbon filter removes cyanoacrylate from the fuming chamber.

The highlight of our filter system, however, is the filter management program. Based on the worst-case scenario, many cyanoacrylate fuming chambers on the market estimate the filter life.

Accuracy is essential, and our filter management system keeps track of the system’s true filter life. As a result, users can tell the system precisely what kind of cyanoacrylate developer they are using and how much of it they are using. In addition, the system will automatically calculate, adjust, and track the filter saturation and indicate when the filter requires replacement, ensuring the maximum life of the filters.