Product Details

Isokinetic probes & Light Blocking isokinetic probes for Climet particle counters.

Background & Science

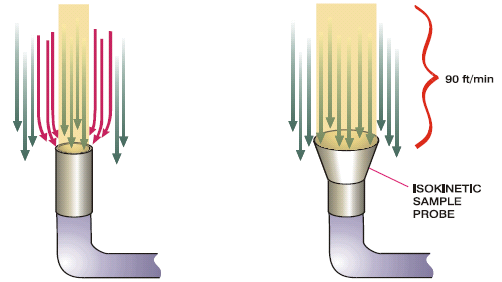

Isokinetic probes are used for two reasons in life science applications. First, smaller particles <1 μm remain entrained in the air stream. However, isokinetic sampling is needed to capture larger macroparticles (> 5.0 μm) that are substantially influenced by inertia and sedimentation (i.e., gravity) that frequently prevents the macroparticle from being pulled into the inlet. Second, isokinetic sampling ensures that particles pass through a defined area within a defined time without disturbing the particle’s path or the surrounding air around the probe (i.e., laminar flow). If there is turbulence around the inlet, which there will be without a probe, it can repel particles belonging to the sample.

Mathematically, the velocity of the particle counter’s flow rate (Vf) must equal the velocity of the particles and air (or gas) entering the nozzle of the iso probe (Vn). Or,

Where, Vf = Flow Rate Velocity of the particle counter, and Vn = Nozzle Velocity of the Particle counter.

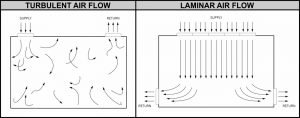

Sampling in cleanrooms is conducted in either Turbulent Air Flow or in Laminar Air Flow areas:

Sampling with isokinetic probes is required in Unidirectional Flow (i.e., laminar flow) areas. (1) (2) (3) (4) These are typically in critical areas, biological safety cabinets, isolators, and RABS. The isokinetic probe, in this environment, ensures air surrounding the particle counter inlet is not disturbed and laminarity is maintained.

Regarding non-unidirectional flow (i.e., turbulent air), Climet conducted testing and highly recommends that isokinetic probes be used in non-unidirectional flow areas when > 5.0 μm particles are a size of interest. Without an isokinetic probe > 5.0 um particles float past the inlet and are not counted, even though they should be part of the sample. The isokinetic probe entrains these macroparticles into the sensor.

Regarding unidirectional airflow (UDAF) areas, during routine monitoring, sample probes should be positioned at work height (not 30″ above the floor per the old FS209E), and pointed in the direction of the laminar flow. They should be positioned in such a way that the probability of detecting particles is maximized, i.e. downstream of the process, and pointed into the airflow that has just passed the product. Where this is not possible, probes should be positioned in the area surrounding the product (within 12″) and not towards clean air flow directly out of the HEPA filter (i.e., not upstream of the process). (1)(2)

In non-unidirectional flow areas, Climet recommends pointing the probe upwards toward the ceiling.

Different Flows & Different Size Probes

Given the aforementioned equation, Vf = Vn, the diameter of the isokinetic probe will vary depending on the velocity of the particle counter’s air flow. The higher the flow rate, the larger the diameter of the isokinetic probe.

For example, when particle counter’s inlet velocity is less than the calculated probe’s nozzle velocity (Vf<Vn), i.e., using an isokinetic probe that is too large, the sample results will be biased high (i.e., over-sampled) due to inertia of large macroparticles > 5μm. Similarly, when the particle counter’s inlet velocity is greater than the calculated probe velocity (Vf>Vn), i.e., using an isokinetic probe that is too small, the sample results will be biased low (i.e., under-sampling) as larger macroparticles belonging to the sample break through the airstream and bypass the probe’s inlet.

Standard Isokinetic Probes vs. Light Blocker Isokinetic Probes

Climet offers two different kinds of isokinetic probes. Our standard stainless steel probes, and our aluminum black-anodized light blocking probes.