General information – Climet CI-302-2x, Stainless Steel High-Pressure Diffuser

The CI-302 High-Pressure Diffuser is used to sample pressurized air or gases with Climet particle counters or microbial air samplers.

Applying compressed air or gases directly to a particle counter or microbial sampler may damage the instrument (e.g., the HEPA filter). Also, particle counters cause turbulence inside the sensor, producing false high counts and gross under-sizing particles. Connecting high-pressure gases directly to a microbial air sampler without a diffuser will result in substantially degrading biological efficiencies due to a high impaction velocity.

The CI-302 regulates the flow rate with an exhaust port to provide a path for the excess air pressure. This allows the particle counter to “pull in” and regulate air or gas flow into the instrument.

Special Calibration & Use

Common compressed gases used in sampling are air, nitrogen, argon, helium and carbon dioxide. The mass flow is affected by the density of the gases being sampled. Air and nitrogen have virtually the same density. However, argon, helium, and carbon dioxide have different densities that shift the airflow. When sampling argon, helium, and carbon dioxide, it is highly recommended that the particle counter or microbial sampler’s flow rate be calibrated for the particular gas being sampled.

Due to safety concerns, Climet does not recommend sampling oxygen.

Cleaning and Maintenance

The CI-302 is compliant with ISO 8573-4 and is autoclavable.

The CI-302 has no moving parts and does not need calibration. Over time, particles may build up on surfaces within the diffuser and require cleaning. If counts become elevated over time, suggesting that the diffuser needs to be cleaned, it is recommended that the diffuser be returned to the factory. Cleaning the diffuser is not indicated as long as counts remain consistently at historical levels.

Interoperability

Interoperability is assured with all Climet microbial samplers and particle counters (excluding the RS version).

A high-pressure diffuser adapter head (p/n: 01210109) is required when used with Climet microbial samplers.

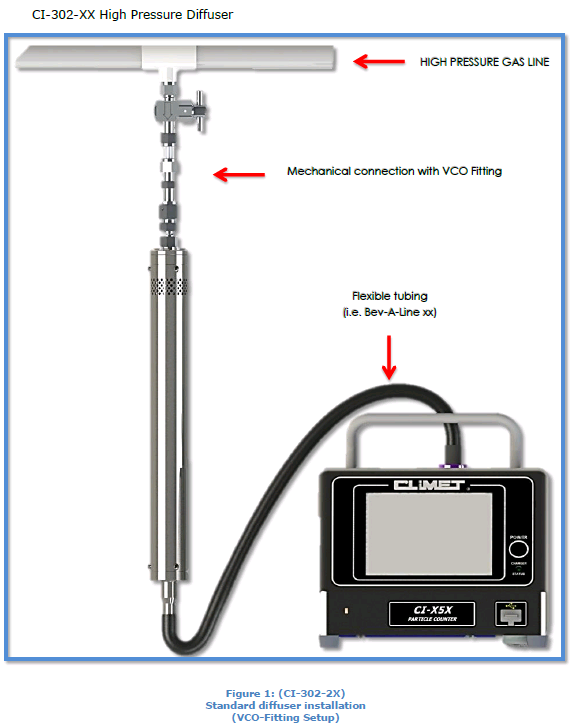

The low-pressure end of the diffuser has a dual-size outlet fitting. This allows 1/2″ or 3/8″ tubing to be connected between the CI-302 and the particle counter inlet or microbial adapter inlet. On the high-pressure end, a 1/4″ tube connection is compatible with several fittings (default VCO).

Configuration & Best Practices

As the flow rate of the particle counter or microbial sampler increases, the narrower the operating range of the diffuser. This may be important when sampling gases with various pressures. Additionally, the following must be taken into consideration during setup:

| • | The inside diameter of the high-pressure gas line can be critical when sampling with 100 LPM. Due to flow restriction, the minimum diameter of the High-Pressure Gas Line (see image below) should be 1/4 inch or larger (ID). If piping is less than 1/4″, we recommend testing with 1 CFM or 50 LPM particle counter or microbial air sampler is recommended. |

| • | High pressure (80 psi and higher) increases gas friction inside transport piping, causing particles to slough off the walls of the piping, resulting in extremely high counts. For these reasons, we normally recommend regulating gases to under 80 psi or sampling with a lower flow rate particle counter. |

| • | Each purchase provides ten (10) feet of 3/8″ and 1/2″ Bev-A Line tubing. This tubing connects to the particle counter or microbial air sampler (i.e., low-pressure end). The minimum tubing length should be ten (10) feet to mitigate sonic waves and false counts. |

| • | A VCO fitting and Teflon valve (i.e., the VCO valve assembly, P/N 01276300) are provided with each purchase. This is recommended to mitigate the generation of particles and provide a secure connection on the high-pressure gas line. The Teflon valve is critical, as users of metal valves frequently require a minimum delay of 5 minutes (while gas is being expelled) to allow metal particles to pass and count to return to nominal levels. Thus, metal valves are not recommended as they frequently result in false high counts, wasted gas, and employee time. |

| • | To mitigate particle contamination of the high-pressure diffuser and contamination of the sensor, start sampling, turn the valve on, and then start the particle counter. When sampling is complete, shut the particle counter off first, then turn the value off. |

| • | When sampling, we recommend not trying to regulate pressure by hand, but instead fully open the pressure inlet (1/2 turn on the Teflon valve), and let the High Pressure Diffuser exhaust the excess compressed gas and do what it was intended to do – – otherwise you risk under sampling. |

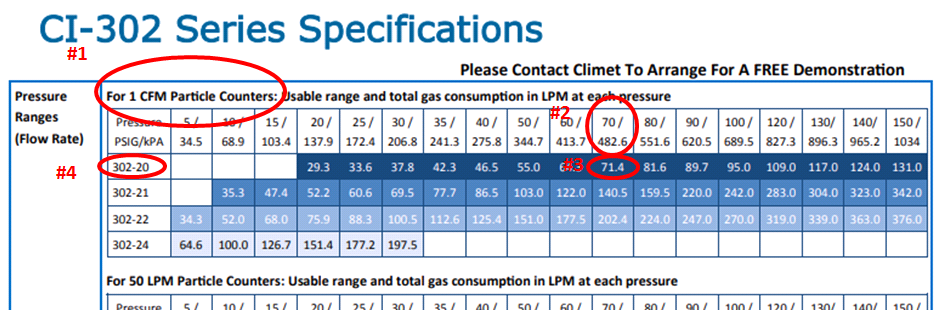

| Step 1 | Can you confirm the flow rate of the Climet particle counter or microbial sampler? This is referred to as the “Low Pressure End.” In this example, we will assume a 1 CFM particle counter. |

|

|

|

| Step 2 | Confirm the pressure of the gas being sampled. This is referred to as the “High Pressure End”. You will want to determine the static gas pressure after the regulator and filter. Let’s assume 70 psi. |

|

|

|

| Step 3 | Drop down to the blue rows, and select the row with the lowest number. In this example, the lowest number is 71.4 |

|

|

|

| Step 4 | Choose the part number (far left column) on the blue row with the lowest number. Again, in this example, the part number is CI-302-20. The last two digits of the part number indicate the orifice size inside the diffuser. Too large an orifice will result in gas waste. |